适用于大批量产品的高性价比 SLT 解决方案

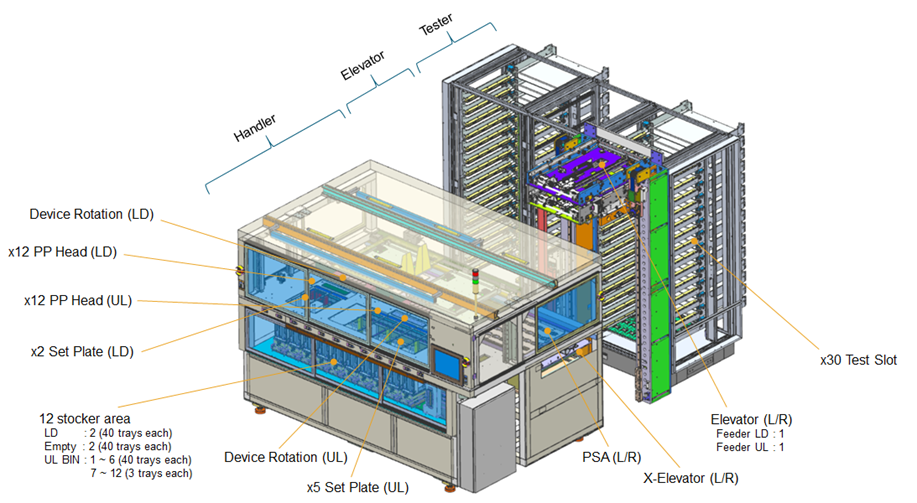

利用 Advantest 的 7038 系统级测试平台发展您的 SLT 战略。7038 是一款全自动、大规模并行、高度模块化的系统级测试平台,可为大批量、高测试时间的产品提供业内最具成本效益的 SLT 解决方案。

7038 可以测试各种集成半导体器件和应用,包括移动、汽车、计算/服务器、人工智能等,并能在 "任务模式 "下验证性能和功能。

全自动大规模并行

7038 是一个全自动测试单元,集成了高速取放装置,用于从测试接口板上放置/移除器件,还集成了升降装置,用于从测试架上插入/移除测试接口板。

7038 能够同时测试多达 720 个 DUT,吞吐量高达 5,000 个/小时 (UPH),测试时间约为 10 分钟。最佳吞吐量与高效工厂占地面积的完美结合,使 7038 成为业内最具成本效益的 SLT,适用于大批量和测试时间较长的设备。

高度模块化和可定制

7038 是一个高度模块化的平台,可进行定制,以支持不同应用和操作条件下的产品;可定制的功能包括:支持带顶部触点的封装上封装 (POP) 器件,支持主动和被动热控制(用于室温和高温测试),支持通过 HSIO 进行结构测试,其中 SCAN、LBIST、MBIST 等结构测试可在 SLT 上运行,并与 V93000/ATE Link Scale™ 的结果相关联,等等。

7038 可进行定制和调整,执行各种测试功能,包括系统级鉴定、系统级验证、系统级鉴定、系统级测试、预烧测试和 RMA/故障调试。

功能包括

-

测试任何集成半导体器件:微处理器、微控制器、蜂窝基带 SoC、调制解调器 SoC 和嵌入式系统

-

测试多达 32 个不同的工单,每个工单都有自己的电压、温度、预烧时间等测试配方

-

实时监控和记录器件温度、电流和功率

-

通过 JEDEC 托盘输入和输出实现交钥匙自动化,包括批量级联、多存储器分选、器件旋转以及最新的集成电路相机和扫描选项

-

易于使用的测试执行软件 ActivATE™

-

极具竞争力的工厂占地面积和器件测试密度

主动温度控制技术(ATC)

7038 利用高精度的温度控制接口来控制每个器件站点。7038 不依赖测试室中的统一温度控制,而是采用直接与器件封装相连的主动热插拔器 (ATI)。每个站点的空气或液体冷却与 ATI 及其 PID 控制回路结合使用。在从冷启动到任务模式和热测试的整个测试过程中,ATC 架构与设备自身的加热系统协同工作。因此,每个站点都有精确的温度管理系统,可用于设备结构测试、预烧测试和系统级测试。

-

7038系统级测试(SLT)和老化测试 (BI) 平台

- 用于实验室和大批量制造调试系统的 7038 单槽测试仪 (SST) 平台

- ATS ActivATE™测试管理软件

- ATS 系统级测试和老化测试服务