Thermal Control Solutions

As we journey deeper into the technological revolution, we observe an increasing trend toward the integration of multiple functions into a single package or device. It's now commonplace for devices to incorporate silicon die, embedding compute, memory, communication, and other functions into one package. This level of integration escalates the power requirements of these devices, often reaching hundreds, if not thousands of watts.

Addressing these escalating thermal challenges is a critical element of test technology across all stages - engineering debug/characterization, Automated Test Equipment (ATE), and System-Level Test (SLT). As these power demands continue to grow, so does the need for test technology to effectively manage these increasing thermal demands.

At Advantest, we understand these challenges and are fully equipped to provide test solutions that enable seamless device operation, even at these high-power levels. We offer a comprehensive suite of thermal solutions tailored to meet the varying needs of devices, ranging from basic passive heat sinks to the most cutting-edge active thermal control solutions currently available.

Our approach to technology development is holistic; we have advanced our thermal solutions concurrently with our state-of-the-art socket solutions, ensuring a comprehensive, single-source solution for our customers, which includes support for leading-edge thermal requirements.

Our offerings also encompass application-specific designs, which can be seamlessly integrated into manual test solutions and semi-automatic solutions. We also offer highly customized designs intended for integration into capital equipment environments.

Advantest is committed to addressing the multifaceted thermal challenges posed by the modern technological landscape. With our varied and innovative solutions, customers can confidently navigate their unique thermal requirements, ensuring optimal performance across a wide range of applications.

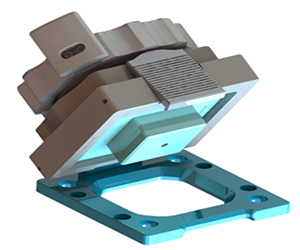

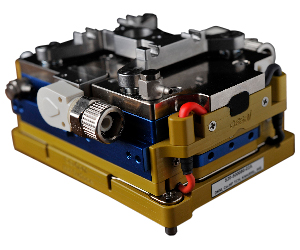

Advanced Active Thermal Control for the most demanding environments

The new "Cobalt" range is the second generation of technology that introduces a unique patented technology. Key features include:

-

Unrivalled highly efficient thermal response with thermo-electric cooler, liquid and heater-assisted technologies

-

Distributed force loading between the die and substrate that prevents silicon cracking

-

Small footprints with excellent test interface connectivity

-

Integrated vacuum pickup

-

Condensation abatement delivering superb cold test capabilities

-

Test interface connectivity

-

Modular construction facilitating rapid customization to a wide range of packages

-

Robust and reliable, with minimum use-cycles into the hundreds of thousands