Optimizing DC Parametric Test Data Analysis and Execution

Advantest Cloud Solutions (ACS) Dynamic Parametric Test™ (DPT) powered by PDF Exensio® focuses on DC parametric test, also known as WAT or e-Test, typically performed in-line during wafer fabrication and end-of-line when wafers are shipping from fab to wafer sort. DPT runs on the V93000 SMU8-based Parametric Test System, enabling greater control of the test flow as a function of the historically - and just-tested available Process Control Monitoring (PCM) data.

ACS DPT™ is jointly developed between Advantest and PDF Solutions, the premier semiconductor data analytics solution provider of the industry. Integrating with the PDF Solutions Exensio® data analytics platform, ACS DPT™ is designed to provide the capability to immediately modify the parametric test plan based upon measured results and other user-defined inputs. The outcome is a system that dynamically adjusts the program flow to collect additional device characteristics from the wafer under test when anomalous measurements or unexpected trends occur. The benefit is a virtually instant reaction to unanticipated wafer characteristics while the wafer is still on the prober's chuck, eliminating lot recall, wafer alignment, and program code modification, to immediately explore the root causes of the just measured data, without the need to modify the original production test program. All of this happens via a “Rule” that defines criteria that when met, triggers subsequent actions to perform steps previously requiring human interaction.

The ACS DPT™ solution provides an interface to define the wafer characteristics to be monitored for deviation from a specified value, statistics, or trend. Once found, DPT is designed to take programmed actions to better understand the device and wafer characteristics in more detail. For example, suppose a spot measurement yields an outlier. In that case, the product or test engineer may want to further characterize the device over a wider stimulus and response range and even explore surrounding die locations for topology mapping. That way, the engineer can determine if the original errant measurement was a one-off point defect or an undesired gradient on the wafer indicating a process equipment issue.

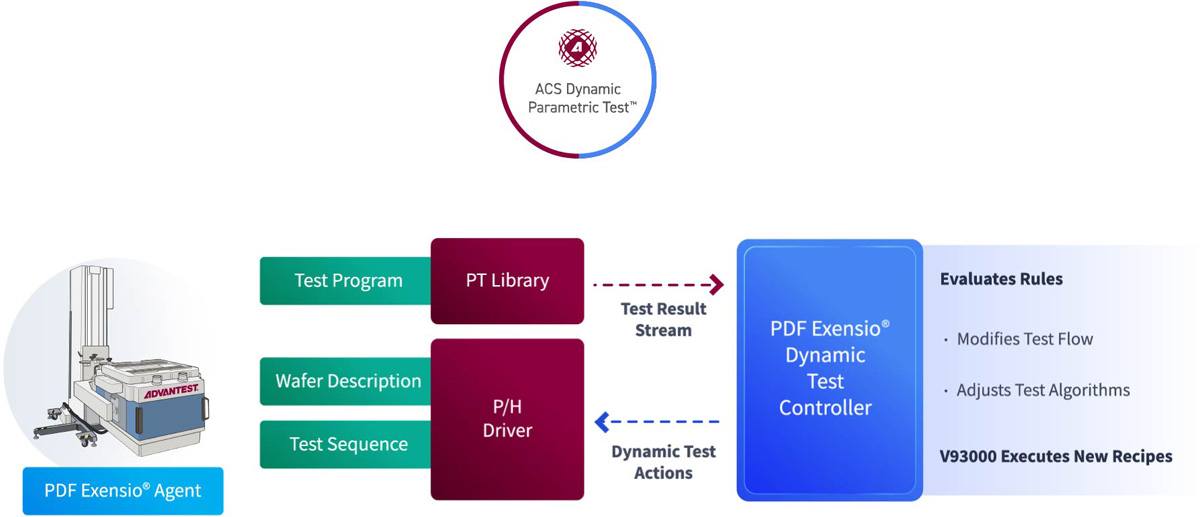

All of this executes automatically through the integrated data flow between the V93000 Parametric Test System and the PDF Exensio® Dynamic Test Controller (DTC) software running on a test floor server. First, the Exensio agent running on the V93000 workstation monitors and sends the test results to the Exensio DTC, which hosts the "Rules Engine" pre-programmed by the test engineer. Then, the Exensio DTC communicates the appropriate rule response action(s) back to the V93000 and prober driver to dynamically adjust the test flow when the action triggers - executing them all automatically.

For more information about the PDF Exensio® platform, visit www.pdf.com

ACS DPT™ Feature Summary:

-

Setup test flow based upon incoming factory data

-

Programmable control over Rules & Actions

-

Monitor test results for further device analysis triggers

-

Automatically execute problem explorations

-

Execute on data across multiple test systems

Your Benefits:

-

Respond instantly, saving tester and engineering time

-

Apply best-known-methods consistently

-

Adjust tester throughput via Rules criteria

-

Generate statistical histories over time

-

Deliver down-stream instructions to wafer sort, package test, and burn-in