Probe needle cleaning on an as-needed basis

Advantest's ACS Adaptive Probe Cleaning™ (APC) solution is an industry-first approach that uses artificial intelligence (AI) algorithms to clean probe needles on an as-needed basis, lengthening probe card lifetime, improving wafer test yield and reducing test costs.

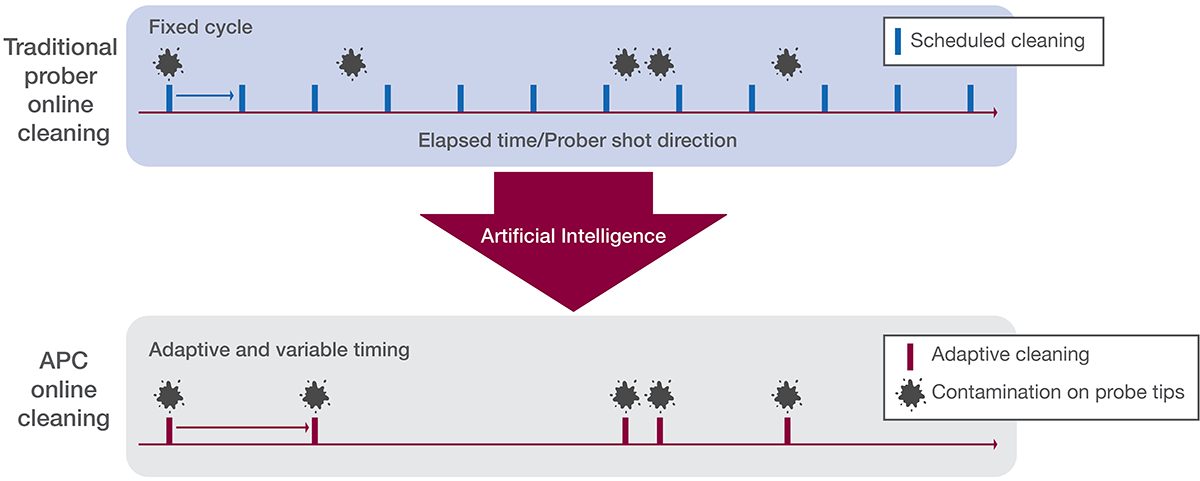

Traditionally, chipmakers have deployed a fixed cycle for the online cleaning of probe needles, using pre-set contact intervals that don’t take into account whether cleaning is actually necessary. This can lead to wide variations in wafer test yield, depending on individual probe card technologies and wafer lots. That approach can also result in high test costs, reduced overall equipment efficiency and shortened probe card lifetime.

ACS APC™ introduces an innovative “adaptive interval” approach to probe cleaning, which optimizes the wafer test process. By using algorithms to conduct real-time assessment of probe needles’ contamination and debris, cleaning will only be performed when necessary to prevent yield from being affected. When connected to the prober and test system, the ACS APC™ AI algorithms first learn trends and characteristics of a test lot from the first wafer. Afterwards, the AI algorithms run adaptive cleaning on the remaining wafers in the lot.

When the algorithm detects an abnormal trend, the ACS APC™ solution immediately assesses the extent of contamination of a probe tip. If cleaning is determined to be necessary, ACS APC™ sends a command to the wafer prober to run the online cleaning process. Since that process can require up to 600 sec of cleaning time, semiconductor manufacturers want to avoid any unnecessary cleaning operation, since it significantly impacts overall equipment efficiency and test cost. The Adaptive Probe Cleaning solution addresses this requirement by optimizing the probe tips cleaning efficiency, reducing the overall wafer lot testing time, while optimizing wafer test yield in parallel. Another benefit is that test-time remains unaffected because the cleaning need assessment takes place instantly in real-time.

ACS APC™ Feature Summary:

-

Implements AI algorithms to assess probe needle contamination and debris

-

Performs across ATE platforms without requiring test program modification

-

Supports all typical mainstream wafer probers and probe card technologies

-

Works with dual probe card cleaning sheets at different cleaning frequencies

-

Utilizes standard GPIB commands to trigger online cleaning procedure

-

Adjusts cleaning cycles automatically

-

Supports parallel test for 2 to 256 sites

Customer Benefits:

-

Improved yield

-

Shortened lot testing times

-

Longer probe card lifetime

-

Reduced probe card maintenance costs

-

Increased system test time availability and overall equipment efficiency

-

Reduced wafer test cell downtime