Stimulus Test Cell

The newest automobiles are required to have good environmental performance and fuel-saving functionality.

Powerful, fuel-saving, low-emissions diesel engines have

particulate filters and oxidation catalysts for purifying NOx and soot in their exhaust systems. In order to maintain the performance of these systems, exhaust gas pressure is

monitored by differential pressure sensors.

The Stimulus Test Cell HA7300 is a test cell which provides an environment for high-speed, highly accurate temperature and pressure test of differential pressure sensors, utilizing Advantest's unique temperature control unit with simultaneous temperature control for 8 devices, as well as a newly developed 2Port pressure controller and pressure application nozzle.

Simultaneous Temperature Control for 8 Devices

A temperature control plate for low temperature or high temperature and a thermal pusher enable temperature control for 8 devices at a time, facilitating high-throughput temperature characteristic test.

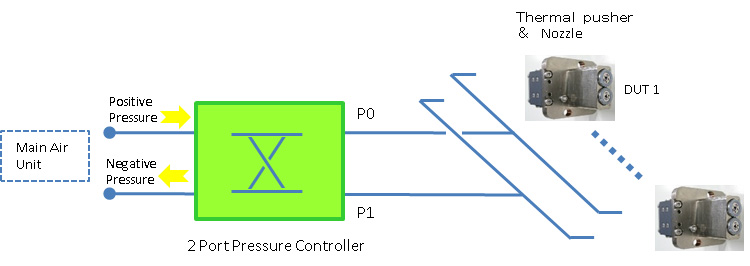

Pressure Application Nozzle

Temperature and pressure can be applied at the same time, thanks to a pressure application nozzle integrated with the thermal pusher.

2Port Pressure Controller

The HA7300's dedicated 2Port pressure controller allows pressure to be applied independently to Port 0 or Port 1, so high-accuracy pressure characteristics can be acquired in a short time.

Test Cell Efficiencies

In combination with the EVA100 measurement system and an Advantest test handler, the HA7300 provides a shared test environment from design evaluation to volume production test.