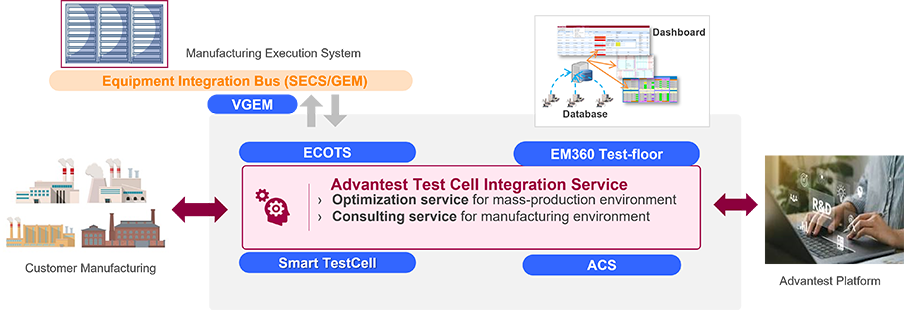

For a new product introduction, a quick production environment setup is essential to time-to-volume. Advantest’s production solution services address the setup to seemly integrate systems into your MES.

VGEM

High volume manufacturing requires the complex integration of multiple manufacturing environments. Virtual GEM (or "VGEM") is Advantest's automation interface which uses industry standard SECS/GEM protocol. This interface solution integrates our test equipment into a factory running SECS/GEM automation.

Customer Challenges

-

Need a centrally controlled production process for high-volume production.

-

Implement SEMI SECS/GEM automation process and require vendor equipment to meet SECS/GEM standards.

Value to Customer

-

Improve processing accuracy due to less operator interaction.

-

Automatically reduces misprocessing due to incorrect manual recipe selection.

-

Reduce the cost of CIM (Computer Integrated Manufacturing) by adopting a SEMI-compliant SECS/GEM protocol so customer does not have to develop different software solutions for different tester platforms.

ECOTS

Unified Test Cell Operating System

ECOTS stands for “Easy Convenient Operation ToolS”, which is a configurable production tool which allows a quick arrangement of equipment driver and features. With Advantest's ECOTS operating system, users can have a seamless interface solution at their fingertips and set up the production environment expediently.

Customer Challenges

-

When equipment from multiple manufacturers are involved, need to obtain interface spec for each component and develop a solution manually.

-

Need a standard OI to integrate testers, probers or handlers to quickly arrange equipment driver and features.

-

Need advanced reports to improve production OEE.

Value

-

Test Cell Operating Interface

-

A seamless interface which connects the tester system, prober, and handler to enable communication from one single interface.

-

Simplify the production setup process and centralize production data collection and reporting.

-

-

Improve Quality

-

Provide real-time data collection, apply rules, triggers and events for production control(YM, SPC, DPAT, ARS).

-

-

Customization

-

Grant flexibility with customers’ specific environment or process under ECOTS framework.

-

Customizable data reporting from test cell.

-

EM360 Test Floor Equipment Management

Engaging Test Floor Intelligence

EM360 is Advantest’s test floor level software solution to help customer manage equipment of the entire test floor.

By having visibility to real-time system HW and SW configurations, equipment status, calibration history, and change history, EM360 enables systematic production planning, asset management and quality management.

Customer Challenges

-

Gathering configuration and change history data manually is cumbersome and prone to error.

-

Need to optimize equipment HW and SW configurations, off-line maintenance, and calibration across a test floor or multiple locations.

-

Need an efficiency KPI measurement regarding equipment management and production management interaction.

Value to Customer

-

Automation

-

Automatically tracks test floor, site, and even the whole company’s current and historic information globally.

-

Automatically generates real-time report and feed into MES system.

-

-

Cross-Site Support

-

Provide cross-site equipment management and upstream-OSAT support.

-

-

Maintenance Management

-

Monitor and remind all maintenance activities to ensure systems in good state.

-

-

Resource Management

-

Save time in tester reconfiguration by identifying hardware resource needs.

-

-

Asset and Utilization Control

-

Manage down to board and license level to improve asset utilization.

-

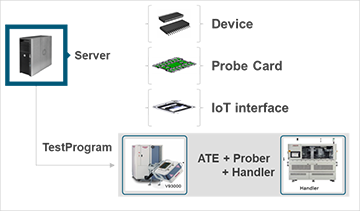

Smart TestCell

Seamless Test Cell Integration Solution

Smart TestCell(STC) are solutions to provide real-time test-cell data collection, recipe management, client execution control, to further unlock opportunities of new applications from test-cell level to test-floor level management.

Customer Challenges

-

Need to bring together different data sources in a test cell environment.

-

Hard to quantify setup spec and identify root cause among multiple parties in a test cell.

-

Need to utilize huge amount of testing and test cell data to improve yield or shorten time-to-volume.

Value

-

Production Intelligence

-

Enable a total test cell solution covering ATE, P/H, docking, setup.

-

Adapt to different production flows, devices, conditions, etc.

-

-

Probe-card Setup Accuracy

-

Validate standard setup spec by sensors of different purposes.

-

Ensure inline production quality by an IoT data transfer framework.

-

-

Test Cell Integration

-

Harmonize heterogenous data from multiple equipment/interfaces/sensors.

-

Unlock new applications opportunities from test cell to test floor level.

-

Contact

For more information or interests in our production solution services, please don't hesitate to reach out to us: