Sockets and Interconnect Solutions

Custom, High-Performance Solutions

Advantest, with its extensive experience in various stages of testing and characterization, is adept at handling the most advanced semiconductors, test hardware, board-to-board, and automated connection cells.

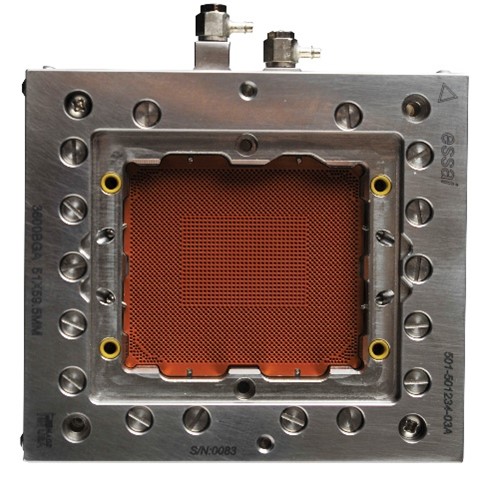

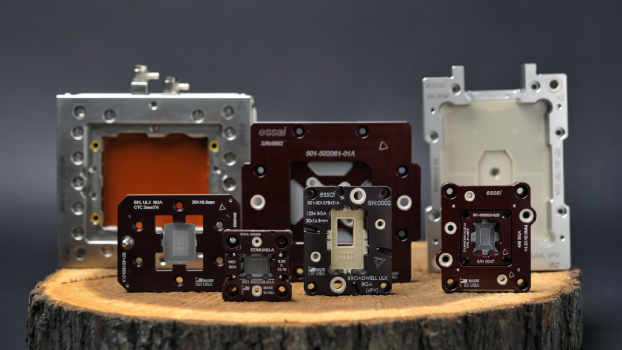

The knowledge and skills gained from working with these advanced technologies are channeled into creating customer-centric solutions. These include specialized socket and interconnect solutions widely used in Automated Test Equipment (ATE), System-Level Test (SLT), and various engineering applications. Key areas where our solutions make a difference are in the highly integrated, High-Power Computing segments, including CPU, Server, GPU, Artificial Intelligence, and System on a Chip (SOC) applications.

At Advantest, we uphold stringent testing standards. Our comprehensive reliability testing covers operating cycles and critical functional parameters, such as force, contact resistance, and deflection. This diligent approach ensures that each component can withstand various challenges in its working environment.

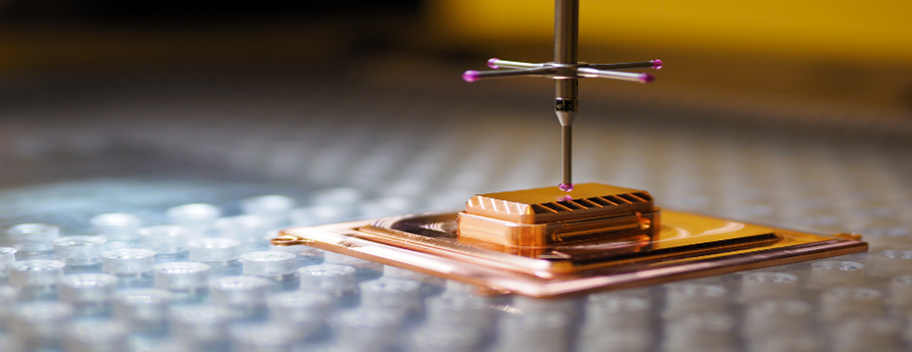

Our analytical lab, equipped with the most advanced inspection and measurement tools, is dedicated to delivering the highest levels of performance and accuracy. These state-of-the-art resources are leveraged to validate our solutions and maintain our unwavering commitment to quality.

Moreover, we understand that high-volume production environments pose unique challenges. Hence, only those solutions that pass our rigorous tests and meet the exacting needs of such environments receive our seal of approval. This diligent vetting process signifies our commitment to ensuring our solutions are well-suited for real-world applications, delivering reliability and performance when our customers need it most.

The range of solutions includes:

-

HVM-proven socket solutions for LGA, BGA, and other packages

-

Custom proprietary "Titan" family of spring probes

-

Low inductance pin options

-

Full height impedance controlled coaxial technology

-

Hybrid/Partial impedance controlled coaxial technology

-

High current carrying probe options

-

PoP package dual-side contact solutions

-

Capital equipment solution integration

Advantest's Advanced Facility: Delivering Global Solutions

Advantest takes pride in its state-of-the-art mechanical fabrication facility, one of the most advanced in North America. Our dedicated teams operate around the clock, staying responsive to the ever-evolving global demands. Our operational model prioritizes flexibility, allowing us to adapt swiftly to our clients' distribution needs and market changes.

All our proprietary production processes fall under a comprehensive, fully auditable ISO framework to ensure the utmost quality. Furthermore, our facility is equipped with highly automated tools designed for uninterrupted operation, ensuring our capability to accommodate flexible manufacturing.

Our robust facility and dynamic operations not only facilitate efficiency but also guarantee adherence to quality standards. At Advantest, we are committed to delivering excellence, and our advanced mechanical fabrication facility is a testament to this promise.

Harmonized Blend of Tools and Capabilities

-

State-of-the-art 5 axis simultaneous CNC Mills

-

Turning and screw machines

-

Electric discharge machining (EDM)

-

Fused deposition modeling (FDM)

-

Custom tooling for increased parallelism

-

"Lights out" production capable

-

In-House high-volume assembly and test

-

Factories for sockets and thermal control units located in Fremont, California, and Phoenix, Arizona