Who we are

Advantest is a leading global semiconductor test provider.Semiconductors are essential components of many products we use in our daily lives.

Increasingly prominent in the infrastructure of digitized societies, semiconductors enrich our world across national and generational borders.

Advantest’s core business is semiconductor test. Our testers are used to determine whether semiconductors operate properly and meet performance and durability requirements. Our reputation for high precision and efficiency undergirds the performance of end products from smartphones to satellites.

We support the safety, security, and comfort of people worldwide by ensuring the quality and reliability of semiconductors.

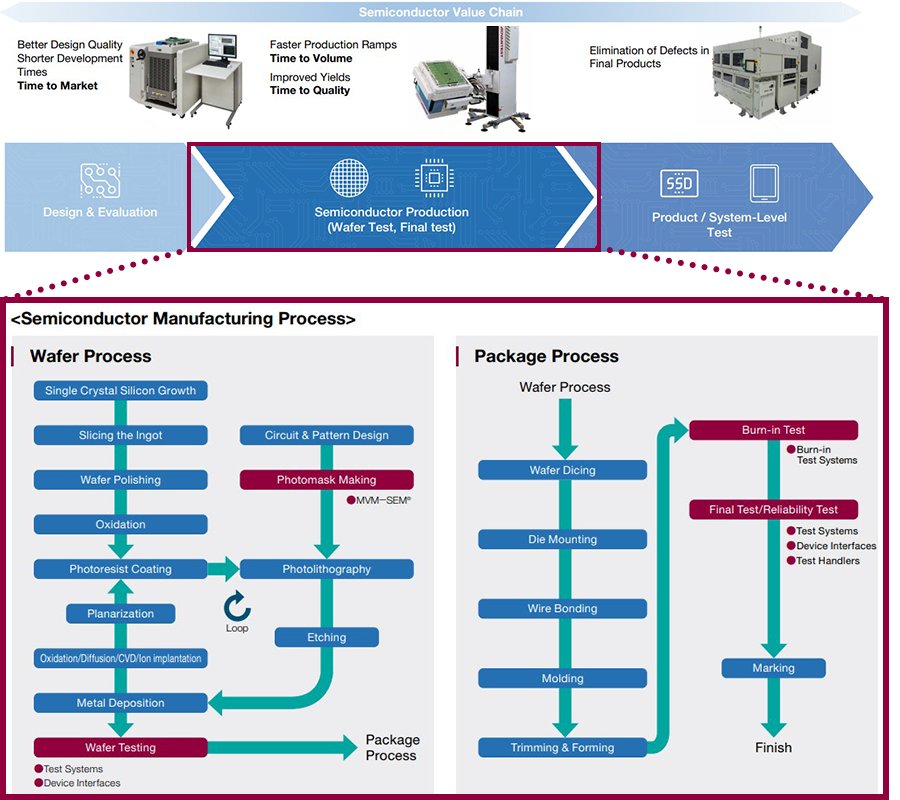

Where We Fit into the Semiconductor Manufacturing Process

Our world-leading technology contributes to the evolution of the semiconductor value chain.

Advantest’s test systems are mainly used at the end of the wafer production process and in the final inspection process, after packaging. In addition, test systems are also used for design evaluation and process development evaluation before volume production begins, and for system-level test after a device is installed in the final product.

As semiconductors have become more sophisticated and complex, it has become more difficult to ensure stable production of high-quality devices.

Helping customers solve their problems with our electronic measurement technology and experience since our foundation in 1954, we continue to support semiconductor innovation.

Semiconductor Test Systems

The Value of Test Systems

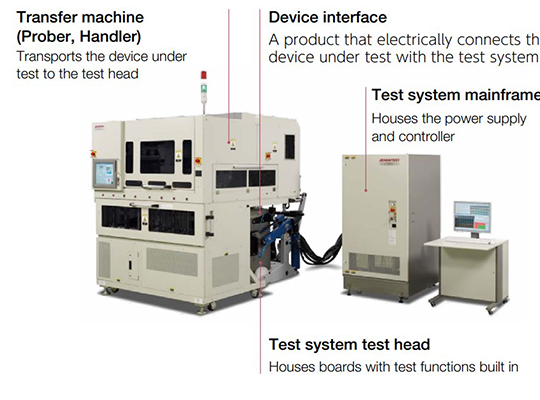

The semiconductors used in various products are so important to the functioning of modern society that they cannot be allowed to fail. However, with semiconductors that operate at high speeds and utilize nanometer-scale circuits, even the smallest manufacturing issues can cause defects such as disconnections or variations in operating voltage and timing. In particular, leading-edge devices pose major technical challenges in terms of manufacturing stability. Manufacturers aim to rapidly achieve high-quality volume production of their devices, in part by thoroughly testing them from the early stages of design all the way through to the production line. Test systems not only perform “final test”, after semiconductors are packaged, but also perform "wafer test” at the end of the front-end process, and are even used at the design and evaluation stages. By analyzing the causes of defects revealed by volume production test and feeding them back to the design stage, yields can be improved, contributing to our customers’ business success. In addition, the modular architecture of our test systems gives them the flexibility to test multiple types of semiconductor devices on a single system.

What Makes Our Test Systems Superior?

Semiconductor test systems have a wide range of points of differentiation, such as measurement quality, test speed, throughput, footprint, and control of heat generation, but the key to achieving superiority on many of these metrics is the semiconductors used in test systems themselves. This is why test system providers design their own semiconductors for use in their products. That design capability is the most important factor in determining the performance of a test system and differentiating it from competing products.

In addition, there are many points of differentiation related to test capabilities and quality, such as the communication network, power supply, mechanism to contact the device under test, and software. Test system providers must have the technical ability to supply a wide range of these capabilities and integrate them into a single system.

Types of Semiconductor Test

There are various types of semiconductors, such as memory devices and SoC devices, for different applications, and each type has different functions. In semiconductor test, a wide variety of "function tests" are performed according to the functions of the device under test. In addition, "timing tests" and "electrical characteristic tests" are also performed.

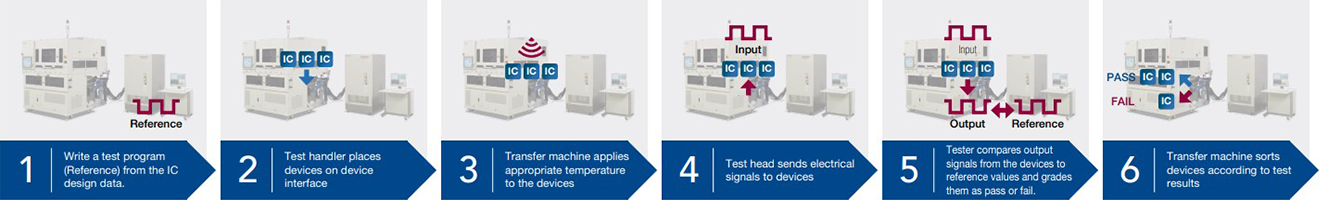

Example of Function Test

The Devices We Test

Semiconductors support global lifestyles.

Advantest's test systems are responsible for testing a wide variety of semiconductors produced by global customers. Our reliability guarantee supports people's lifestyles worldwide.

-

These devices symbolize the evolution of semiconductors and resulting smartphone performance gains. Application processor test is uniquely complicated due to the adoption of state-of-the-art semiconductor processes in their production, whilst manufacturers are also actively investing in test systems.

-

These ICs control the color and brightness of displays on products such as smartphones and televisions. In the display industry, technological evolution is driving rapid new developments such as the adoption of organic EL, larger screens, higher definition, narrower edges, and incorporation of touch sensors, so display driver IC test is becoming more complex.

-

These semiconductors convert DC to and from AC and adjust voltage, among other functions. They have a wide range of applications in addition to consumer electronics, including automobiles, industrial equipment, and wind solar power generation. The power device market is expected to grow in the future amidst increasing public demand for lower power consumption.

-

This is a general term for semiconductors for high performance computing (HPC), which are designed to perform large-scale operations at high speed on data servers and AI servers. With the spread of AI, machine learning, and deep learning, the HPC device market continues to make yearly strides.

-

Semiconductors that store data include DRAM, which can read and write data at high speed, and NAND flash, which can hold data for a long time without a power supply. In recent years, demand from the smartphone and data center sectors has been increasing.

-

These semiconductors convert camera images into digital data. In addition to the trends toward higher image quality and multi-lens cameras in smartphones, rapid progress in response to highspeed image data processing amidst growing demand for video has created new needs for higher test system performance.

-

Radio Frequency ICs handle wireless communications. Their main applications are smartphones and base stations. With the expansion of 5G into the millimeter-wave band, expectations are rising for test solutions that address these technological trends.

-

This is a general term for semiconductors installed in automobiles, such as controllers for engines and batteries, sensors for airbags and collision avoidance systems. High quality and reliability that meet the safety standards of automobiles are required, so it is necessary to carefully test these devices.