We understand the impacts our business activities have on the planet's environment and we carry out activities to reduce our environmental impact. This page introduces our initiatives for environmental conservation.

Green Products

Basic Stance

Contributing to the sustainable development of society and conducting environmentally friendly business operations are essential issues that need to be addressed in modern business management. The Advantest Group works to develop products from the perspective of environmental conservation while prioritizing high precision and high quality, and certifies as green products those products that are environmentally friendly in terms of the three key aspects of energy and resource saving, improving recyclability, and elimination of hazardous substances. There is demand in society for the supply of green products because they provide both a reduction in the environmental footprint and an improvement in economic value. The Advantest Group has been promoting business activities based on the belief that providing green products will be in response to these demands and beneficial for its customers since 2005.

Development Flow of Green Products

At the Advantest Group, all products undergo a product environmental assessment.

During the product environmental assessment, products are assessed from various aspects, including energy-saving, reduction of the number of components, size reduction, recyclable design, and elimination of hazardous substances.

New products that meet the Voluntary Standards for Green Products defined by Advantest are certified as green products and are awarded with an Eco Label (type II), in addition to the product environmental assessment. We design new products to be 100% green products.

Advantest Group Eco Label

The Advantest Group Eco Label features an original three-color design representing energy and resource saving, recyclable design, and elimination of hazardous substances through green procurement.

Energy and Resource Saving

We aim to reduce the environmental impact of our products through product designs that save energy, reduce components, and reduce size.

The reduction rate of energy against conventional products has been set to a standard of at least 20% for semiconductor test systems and measurement instruments, and at least 10% for other products such as handlers and nanotech products.

We have also set a reduction rate of at least 10% in the same way for components and the miniaturization for all of our products.

Note: The above reduction ratios are values based on performance computation.

Recyclable Design

In recyclable design, we release information on parts that will require special attention during disposal, and plastic parts designed in-house use 90% or more recyclable materials. Moreover, we make sure that products are easy to dismantle with standard tools, and we use rechargeable batteries displaying a recycle symbol.

Elimination of Hazardous Substances (Green Procurement)

To eliminate hazardous substances from our products, we have established Group standards on banned substances based on the IEC62474 standard, and we conduct surveys of hazardous substances contained in parts and materials used in our products. Advantest is building a response system for some of its products and eliminating relevant chemical substances using the results of this survey because these chemical substances are regulated by the RoHS directive as of July 2017.

Our main products are semiconductor examining devices, which are not manufactured products. Therefore, our main products do not cause emissions of gases such as PFASs.

Green Products Certified During Fiscal 2024

In fiscal 2024, a total of seven products related to semiconductor test systems, test handlers, and electronic measurement and medical equipment were certified as green products.

Promoting Product Reuse/Recycling

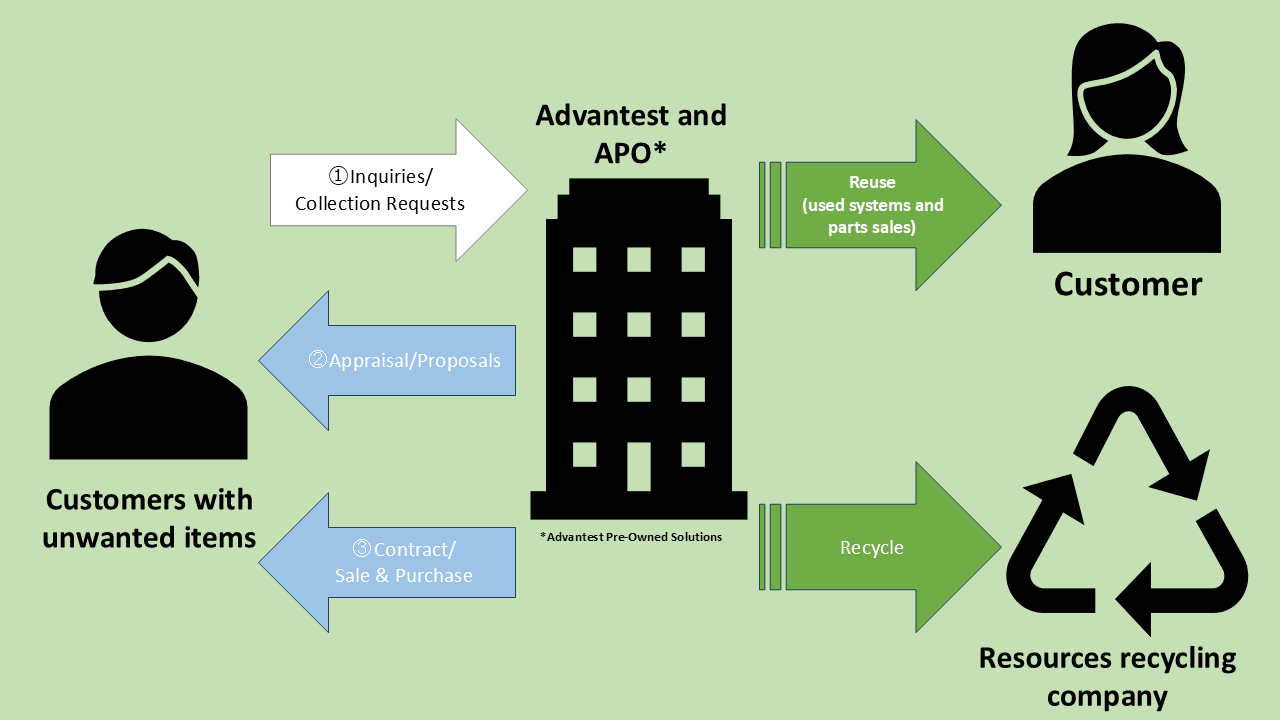

Advantest has been engaged with product reuse/recycling activities through Advantest Pre-Owned Solutions Co., Ltd. (APO), our subsidiary. Along with APO, Advantest not only provides maintenance support for products, but also tries to respond to a variety of customer requests, until the products are no longer in use.

For customers who no longer need our products, Advantest contributes to "reduce" by purchasing them instead of simply disposing of them. Advantest also promotes the “reuse” of our products across our entire customer base network by reselling purchased equipment to other customers who have used it for a long time, or by providing parts.

If there is no demand for the equipment or parts, Advantest implements initiatives to "recycle" the equipment it takes back by sorting it into resource levels.

Product Reuse

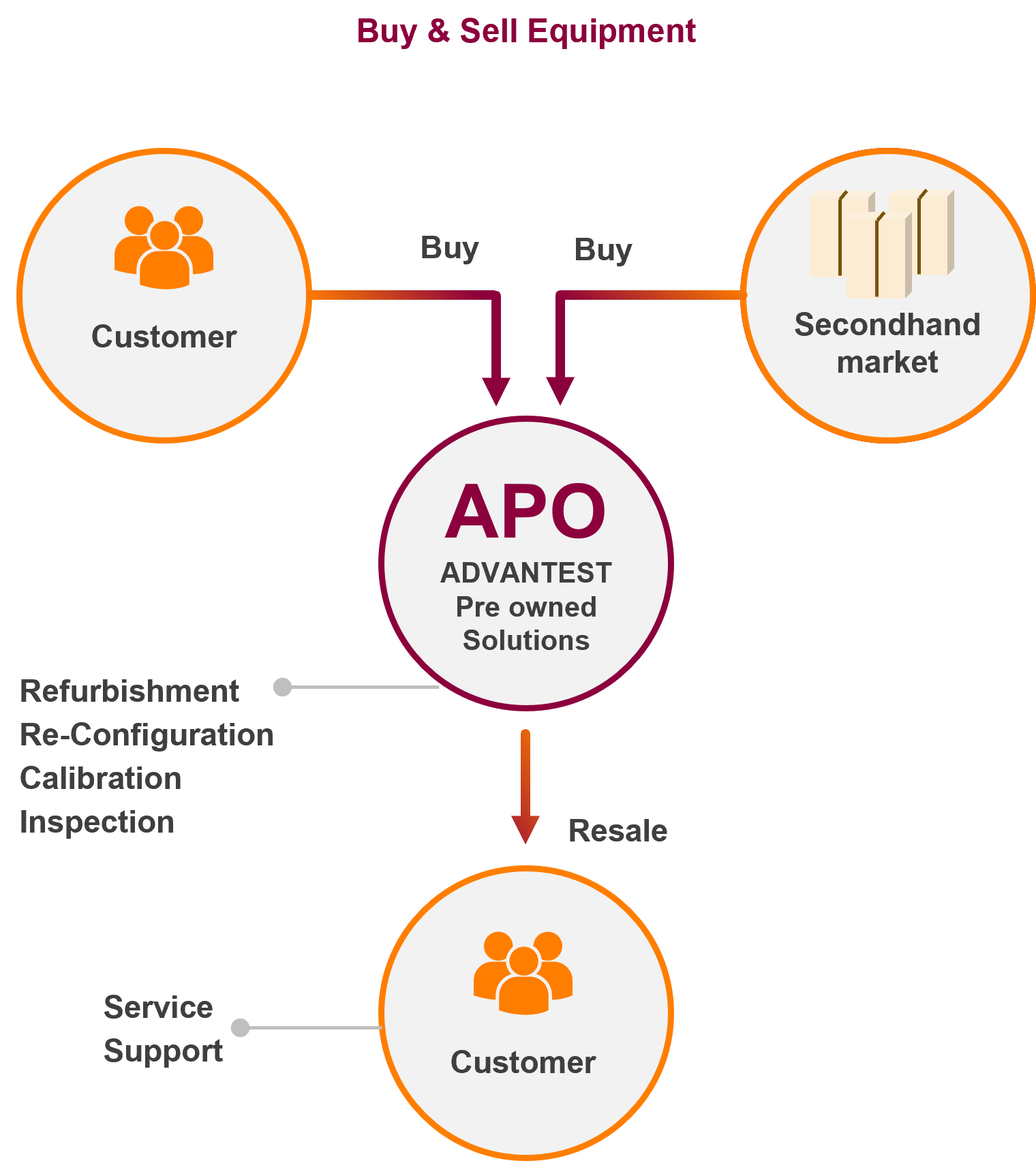

Advantest buys back and resells products through APO.

Advantest purchases equipment from customers who no longer need our products and resell it with a one-year warranty to customers who still wish to use it after our engineers modify specifications, check operation, and switch licenses. Advantest also provides maintenance support after sale, just as it does for new purchases.

Provide safe and secure used system with guaranteed performance

-

Buy back test systems from customer or market

-

Delivers refurbished and/or reconfigured equipment with the certified parts

-

Resale pre-owned test systems

-

Offers system installation and maintenance programs

Product Recycling

Basic Stance

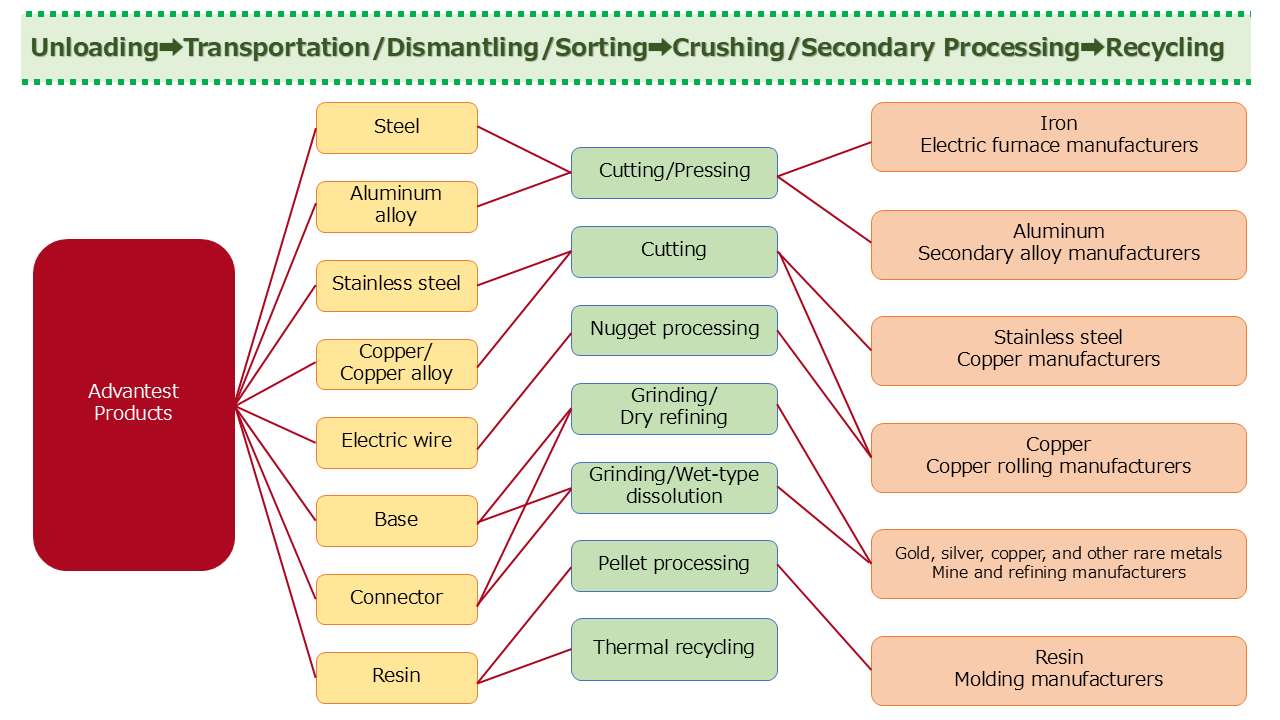

It is the Advantest Group's basic policy to take active steps to ensure that the products we sell are recycled after they are retired. As a basic policy, we buy back products that are not expected to be reused so that the resources can be recycled.

Recycling policy

-

1.Achieve 100% collection of recyclables through manual dismantling.

-

2.Clarify to whom recycling is to be commissioned, and ensure traceability.

-

3.Promote the conservation of the global environment in collaboration with customers.

-

4.Properly dispose of harmful substances.

(Hazardous substances: mercury relay, ion type smoke detector, internal cooling water, and Fluorinert)

Recycling Results for Fiscal 2024

At the request of our customers, we engaged in resource recycling. The following is a list of the results.

Advantest's product recycling system ensures proper disposal of used products, a high recycling rate (over 90%), and recycling of resources at reasonable costs.

Benefits for Customers

-

Based on the technical information of the products we have provided, expert staff at the recycling facility may dismantle and separate components containing valuable materials or hazardous substances and recycle them in an appropriate manner.

-

Upon request, Advantest may issue a "Recycling Certificate."

Currently, resource recycling is a domestic Japan-only solution, but we will continue consider its global applications and expand our activities.

Contact Information

Operational practices, quotes, individual contracts with customers, recycling cost reimbursement, etc.

Advantest Pre-Owned Solutions Co., Ltd. (APO)

(Secondhand dealer license: Tokyo Metropolitan Public Safety Commission No.301011008681)

- TEL

- +81-3-3214-7500

- pdl-afi-inq@advantest.com

Initiatives to Address Supply Chain Emissions

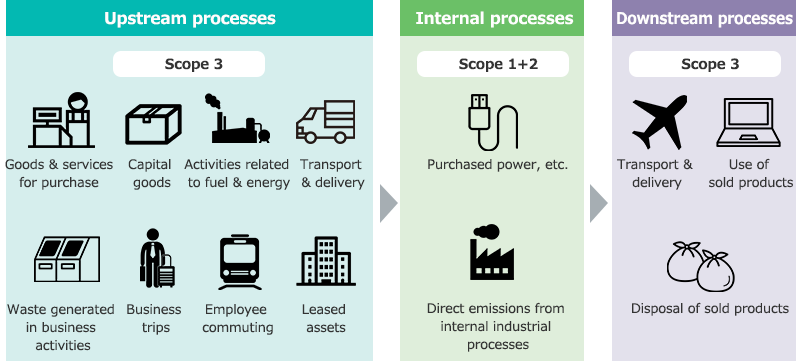

Efforts by individual companies alone to address climate change will have only a limited effect, which prompts us to engage in initiatives involving the entire supply chain and industry associations. The Advantest Group will proactively work to reduce our environmental footprint over the mid- to long-term through our supply chain in order to reduce supply chain emissions.

Supply chain emissions = Scope 1, 2 and 3 emissions

Task Force to Promote Supply Chain Emissions Reduction Activities

We have established a task force in FY2021 to promote supply chain emission reduction activities and have been working on these activities throughout our supply chain ever since to achieve the SBTi certification targets for Scope 1 + 2, 3.

In our entire supply chain, Scope 3 "Category 1 (C1): Purchased products/services" and "Category 11 (C11): Usage of products" account for the majority of GHG emissions. In addition to our own Scope 1+2 emissions reduction, reduction in Scope 3 "Category 1 (C1): Purchased products/services" and "Category 11 (C11): Usage of products" represent a significant challenge for us.

(1) Task Force 1: GHG Emission Reduction Activities Through Product Development (Scope3 Category11)

Sustainability Action Plan 2024-2026

Task Force 1 will collaborate with our R&D departments worldwide to promote the reduction of GHG emissions.

In our Sustainability Action Plan, we set the goal of improving the environmental performance of our products, with the GHG emission per AT innovations reduction rate serving as a KPI. Progress in FY2024 achieved an 84% reduction. We will continue to strive to meet the FY2026 target by enhancing product specifications and contributing to GHG emission reductions through product development.

(2) Task Force 2: GHG Emission Reduction Activities Through Cooperation with Business Partners

Sustainability Action Plan 2024-2026

Task Force 2 will work with the procurement department to support the reduction of GHG emissions by promoting the use of renewable energy among our suppliers.

In our Sustainability Action Plan, we have also set the goal of decarbonizing our supply chain and have adopted the percentage of our major suppliers adopting renewable energy as a KPI, with progress in FY2024 at 52%. We will continue to ask our major business partners to cooperate in the introduction of renewable energy in order to achieve the target for FY2026. As part of our request for cooperation, we conduct an annual “Supply Chain CSR Survey” among our major suppliers. Through this questionnaire, we have ascertained the status of suppliers' introduction of renewable energy and provided individual feedback based on analysis and evaluation of the survey results. By means of these activities, we will promote suppliers' use of renewable energy by helping them understand the necessity and importance of reducing GHG emissions.

In addition, in Scope 3 Category 1 (purchased products/services), the challenge is to break away from the method of calculating GHG emissions, which increases in proportion to the purchase price. We will consider promoting reductions by establishing a calculation method in which the Scopes 1, 2, and 3 values of our suppliers are reflected in the GHG emissions of Scope 3 Category 1 (purchased products/ services), and by requesting suppliers' cooperation in reducing GHG emissions as listed under Scopes 1, 2, and 3.

(3) Task Force 3: GHG Emissions Reduction Through Collaboration with Our Customers

Task Force 3 will work together with the sales department to promote the reduction of GHG emissions through collaboration with our customers.

Through dialogue with our customers, we share their policies and goals regarding climate change. We will also aim to understand policies and targets our customers have established to deal with climate change, and contribute to reduction of GHG emissions through collaboration with our customers as a member of the supply chain. At the same time, while considering our desires and expectations for their suppliers, we will distill and incorporate them into the roles we ought to play and the issues we ought to tackle through our strategies, and will reflect them in our Sustainability activities. In addition, in Scope 3 Category 11 (use of sold products), the challenge is to break away from the calculation method of GHG emissions that increases in proportion to the number of units sold. We will consider promoting reductions by establishing a calculation method that reflects customers' renewable energy values in Scope 3 Category 11 (use of sold products) and by requesting cooperation in increasing customers' renewable energy installation rates.

(4) Task Force 4: GHG Emissions Reduction Activities in Business Operations

Sustainability Action Plan 2024-2026

Task Force 4 aims to reduce GHG emissions from our business activities through the introduction of energy-saving equipment and renewable energy.

In our Sustainability Action Plan, we have set the goals of reducing GHG emissions and introducing renewable energy in Scope 1+2, and have been promoting activities with the GHG emissions reduction rate and renewable energy introduction rate as KPIs, respectively. With the introduction of renewable energy at our domestic sites reaching almost 100%, and the introduction of renewable energy at our Korean sites starting in FY2024, we have achieved a GHG emissions reduction rate of 76% and a renewable energy introduction rate of 87% in FY2024, both of which have far exceeded the FY2026 targets. In order to further reduce emissions going forward, we will be expected to introduce more renewable energy, however, the challenge is to introduce renewable energy in regions such as South Korea, Taiwan, and Singapore, where renewable energy supply is inherently limited and difficult to purchase. Through RE100 initiatives, of which we are a member, we expect to encourage governments to increase the supply of renewable energy, while we continue to survey the status of renewable energy in each country to find clues to promote the introduction of renewable energy.

-

*1Please refer to "Management" for the list of CxOs.

-

*2GHG emission per AT innovations is calculated by dividing Scope 3 Category 11 GHG emission by AT innovation (number of transistors based on Advantest's market share, pins, frequency, DPS current in systems that account for 80% of annual sales, and number of the systems).

-

*3The top 85% of suppliers by transaction value are defined as main business partners.

Climate change initiatives at our domestic locations

Introduction of Renewable Energy

Starting with the transition to 100% renewable energy at the Gunma Factory in 2021, we have also transitioned our Head Office, Gunma R&D Center, Saitama R&D Center, and Sendai Laboratory to 100% renewable energy. As a result, approximately 100% of the electricity used at our domestic sites is now powered by renewable energy sources.

Climate change initiatives at our overseas locations

Introduction of Renewable Energy

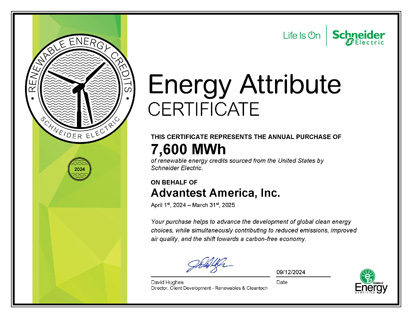

AAI has been purchasing Green Electricity Certificates for wind power generation since 2012 and obtains approximately 100% of its electricity from renewable energy sources. Furthermore, in 2012, AAI joined the Green Power Partnership, an initiative by the United States Environmental Protection Agency (EPA) to promote renewable energy and support the expansion of green electricity.

Since January 2025, AAI has been expanding this effort by installing solar panels on two buildings in Arizona to reduce AAI’s GHG impact and alleviate the energy strain on our community.

(United States)

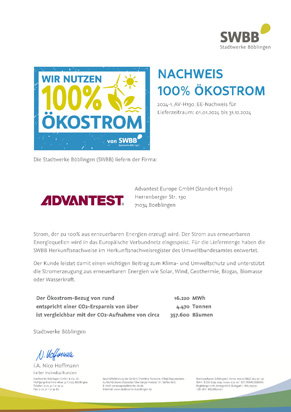

Advantest Europe GmbH (AEG) has been implementing renewable energy since 2019. AEG has introduced renewable energy sources such as solar power generation, and sourced approximately 100% of its electricity used from renewable energy sources ever since.

(Germany)

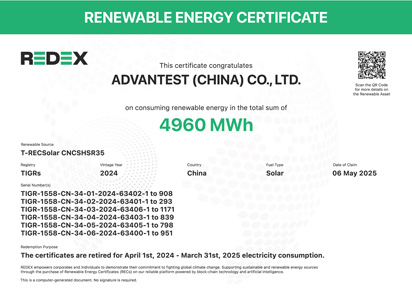

Advantest (China) Co., Ltd. (ATC) has been implementing renewable energy since 2022. ATC has purchased a Green Electricity Certificate for solar power generation, and sourced 100% of its electricity used at the business sites from renewable energy sources.

(China)

Recycling Resources

The Advantest Group pursues operations encompassing the "3Rs" (reduce, reuse, and recycle) with the aim of realizing a recycling society.

Waste recycle initiatives

The Advantest Group is committed to converting waste into valuables by reinforcing the initiative we launched in FY2009 to separate components. We ensure strict compliance in these activities.

In disposing of waste (including packaging materials) generated in our business activities, we clearly indicate to our outsourcing contractors the disposal method for each classification as per the relevant laws (including local laws and regulations) to ensure proper disposal and recycling by material type.

Trend in waste generated and recycling rate

-

*The amount of waste generated, and the amount of waste recycled in Japan were calculated excluding valuable materials.

-

*We found, through an inquiry to a waste disposal contractor, that some generated waste which had been allocated to the recycled quantity was not in fact recycled. We have recalculated and restated the past figures accordingly.

Efforts to Eliminate Plastic

For more than 15 years, Advantest Gunma Factory has used reinforced cardboard packaging to transport our products, such as test systems, contributing to the elimination of plastics and the reduction of waste. In addition, reinforced cardboards are also used for the pallets on which the products are mounted, thus achieving a reduction in plastics. Currently, plastic accounts for less than 6% of our packaging materials.

The cardboard boxes are manufactured in appropriate sizes with the cooperation of our cardboard suppliers, which serve vital roles in providing safe and efficient deliveries. Moreover, the cardboard boxes are about half the weight of the wooden boxes used in the past, not only contributing to reducing CO2 emissions during product delivery but also reducing the burden on employees since they are not just easy to pack, but are also easy to unpack at the shipping destination. A single cardboard packaging material is used only once for transporting a single product, and is recycled based on the rules of the customer.

Realizing a New Circulation Cycle with the Introduction of a Recycling Equipment

Advantest has installed a recycled paper manufacturing machine from 2020, which can produce new paper from used paper such as rejected documents. With this machine, most of the confidential documents to be disposed, which were hitherto collected and sent to a contractor for disposal, will be processed in-house, and given "new life" by being recycled into paper and made use for various purposes, such as business cards.

We also made notebooks using recycled paper and gave them as gifts to local elementary school students who visited our biotope for nature observation events, as well as to special-needs school students and teachers who paid a visit during our company tours. These help in view of our social contributions by providing teaching materials for learning applications.

The equipment is operated by our employees with disabilities. It will also create more opportunities for people with disabilities to play an active role in the company. Once they embark upon their careers and showcasing their active roles as members of the Advantest Group will prove to be a way to repay their alma mater. With the introduction of the new paper manufacturing machines, Advantest has realized a new circulation cycle through various aspects such as environmental commitment, employment of people with disabilities, and educational support.

For more information on employment of the disabled, please refer to "Efforts to Promote Diversity".

recycled paper

manufacturing machine

Proper Disposal of Waste Plastics and Material Recycling

Advantest has been recycling all waste plastics at business locations in Japan.

At its Gunma Factory, trays and magazines, which are used as parts containers, are disposed of as waste plastics.

Individual employees check the recycling identification mark on each container to sort containers containing PVC.

This allows waste plastics to turn into the main raw material for RPF (Refuse Paper & Plastic Fuel), which is a high-quality solid fuel.

Waste plastics containing PVC are crushed, incinerated, and recycled as molten slag, which is used mainly as roadbed material.

Proper Disposal of Equipment Containing PCB

Advantest owned three capacitors, fluorescent lights, and stabilizers that contained polychlorinated biphenyls (PCBs), but all pieces of the equipment that contained PCBs were properly disposed of during FY2017.

Effective Use of Water Resources

Advantest's main usage applications of its water resources are the operation of air conditioners, kitchen use, toilet cleaning, and drinking. At our main bases, we use water for industrial use efficiently. In addition to using this water for cleaning the toilets, we also use it with roof-mounted sprinklers to improve cooling in the summer. Advantest is also filtering drinking water and using ultra-pure water at some business establishments. It should be noted that approximately 90% of the discharged water produced by Advantest Group is classed as domestic sewage. Currently, domestic sewage and rain water cannot be recycled.

Of course, every member of our staff takes care not to waste water, and strives to make effective use of our water resources.

Trend in water usage/discharged water